By Thijs in Blogs 11/10/2023 · 9 minute read

Capsule filling machines play a pivotal role in embedding various substances such as pharmaceutical or nutraceutical ingredients, in a form that can be powder, granules, tablets, or liquids, into empty capsules.

This sophisticated machinery, especially industrial capsule fillers, is pivotal for large-scale manufacturing, ensuring the procedures remain both proficient and efficient.

With the optimal capsule filling technology, FOREFRONT Nutraceuticals transforms a potentially intricate process into a system that promises speed, accuracy, and most importantly, precise dosing with minimal wastage. The encapsulation process may produce varied capsule types and, thus, different machines cater to specific needs and scale.

Capsule filling machines broadly classify into three types:

· Manual Filling Machines

· Semi-automatic Capsule Filling Machine

· Automatic Capsule Filling Machines

Manual Capsules Filling Machines: Precision in Every Capsule

Manual Machines are designed for industries requiring precise ingredient measurements in each capsule, providing a reliable method to create customized capsules. Capable of producing around 800 capsules per press, these machines feature a powder tray and loading trays with a capacity of 300 holes, ensuring efficiency and accuracy in every operation.

Semi-automatic Capsule Filling Machines: Striking the Perfect Balance

Semi-automatic Machines, as the name suggests, seamlessly combine manual and automatic processes, reducing reliance on operators while meeting industry hygiene standards. These machines are durable and low-maintenance due to their non-corrosive components, efficiently filling both powders and granulated substances. Their ability to blend human control with automated functions makes them an ideal choice for businesses aiming for a balance between manual operation and full automation.

Comparing Semi-Automatic and Automatic Capsule Filling: Making the Right Choice

When it comes to semi-automatic capsule filling machines, they integrate manual and automatic processes, reducing the need for human intervention while maintaining industry cleanliness standards. These sturdy machines require minimal maintenance and excel at filling powders and granules efficiently. They serve as a middle ground between manual labor and complete automation, making them a preferred choice for many businesses.

In contrast, automatic capsule filling machines are tailored for large-scale production, eliminating the need for human involvement entirely. These advanced machines handle various powders and granules, catering to diverse production needs. They seamlessly integrate with other equipment such as capsule polishers, dust extractors, and empty capsule ejectors, streamlining the entire production process. Not only do these machines enhance productivity, but they also ensure consistency and precision, making them indispensable for high-volume manufacturing.

Automatic Capsule Filling Machines

Automatic Machines are designed to fill capsules at a large scale without operator dependency. These machines can accommodate various particle powders or granules and can link to supplementary equipment like capsule polishers, dust extractors, and an empty capsule ejector.

The Capsule Filling Process: Step By Step Explained

Capsule filling machines typically follow a systematic 5-step process:

Feeding: Capsules are loaded and channeled, ensuring correct alignment before reaching the spring-loaded end for filling.

Separation: The vacuum system opens the capsule, with any improperly separated capsules identified and discarded.

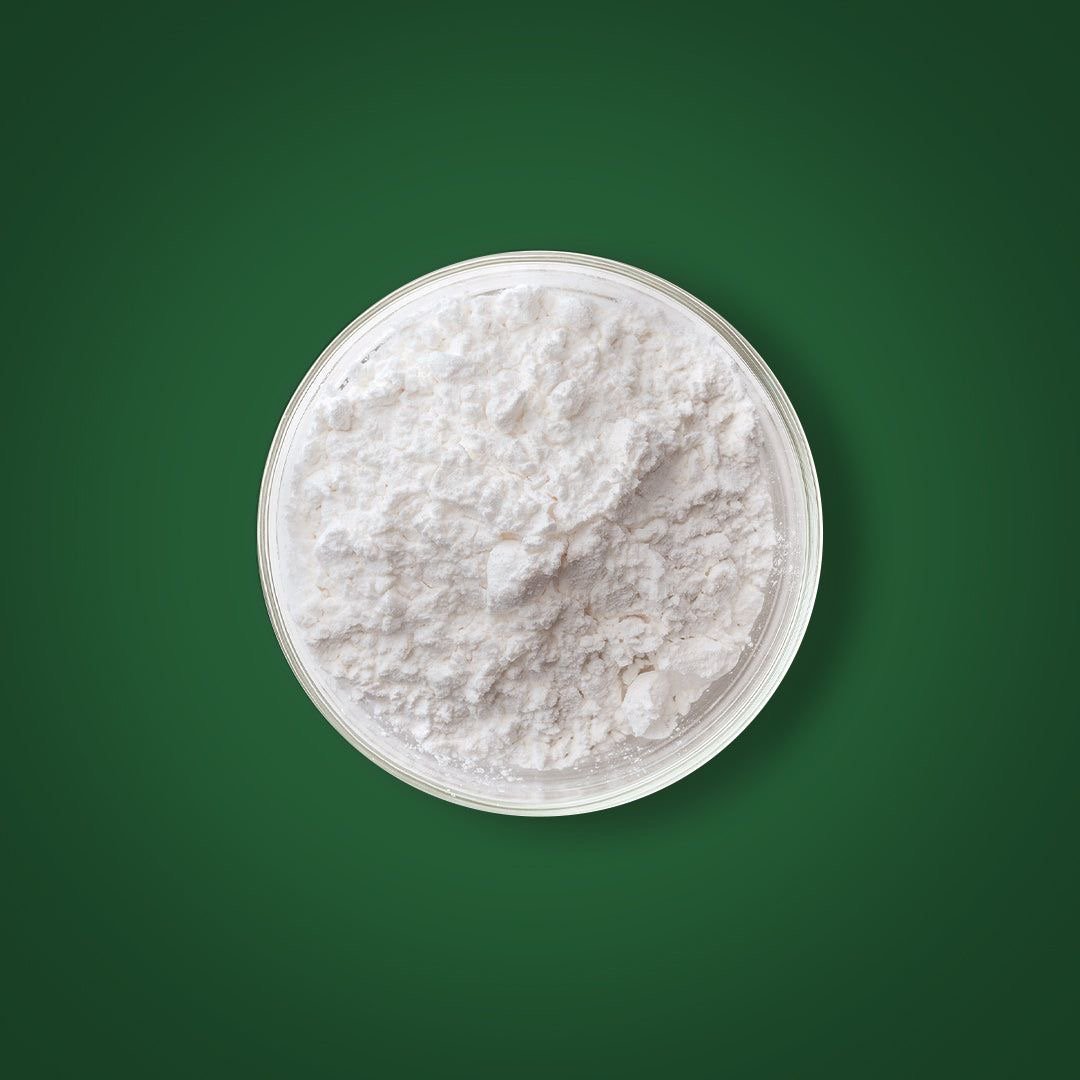

Filling: The manner of filling varies, with options such as tamping needle mechanisms for powders or different methods for liquids.

Completion: The machine aligns and locks the capsule bodies and lids together.

Discharge: Once sealed, the capsules are ejected, cleaned, and prepared for distribution.

A capsule filling machine is indispensable for expedited capsule production within the pharmaceutical and nutraceutical sectors.

Understanding which machines align optimally with your business needs ensures you select the most precise and dependable one for your product’s manufacturing.

FOREFRONT Nutraceuticals – Your Comrade in Capsule Filling.

With our years of expertise, our technical service experts stand steadfast in ensuring your capsule filling operations run seamlessly and efficiently. This seasoned team perennially visits customer factories, assisting with filling processes, embodying our unwavering commitment to quality and value.

Your journey starts by identifying the optimal capsules for your filling material. We guide you through ensuring your selected capsules not only deliver outstanding results but also function smoothly within your capsule filling machines.

Enhanced tuning and setup of your machinery augment its productivity, enabling swifter, cleaner, and more efficient operations, thereby elevating both quality and performance.

Contact Us Today

Our Technical Service Department is poised to assist you in designing or augmenting your capsule manufacturing department, recommending the most suited equipment, and determining your layout. Despite our deep familiarity with various equipment options, our absence of affiliations with manufacturers guarantees you impartial advice, ensuring your budget, space, and capacity requirements are met with the best solution.

Looking for more information regarding capsule filling machines or high quality empty capsules? Contact us here.