Probably you have been comparing price quotes from various manufacturers for empty capsules. And you’re likely aware of the substantial price variations among different brands. In an industry where profit margins are consistently under pressure, the temptation to choose the cheapest option can be strong. After all, a capsule is a capsule, right?

However, that assumption couldn’t be further from the truth. All empty capsules are not created equal, and quality is a crucial factor. In fact, the quality of capsules can have a profound impact on the filling process. It will turn your seemingly “budget-friendly” capsules into a costly choice.

Low-cost Capsules Lead to Low Yields

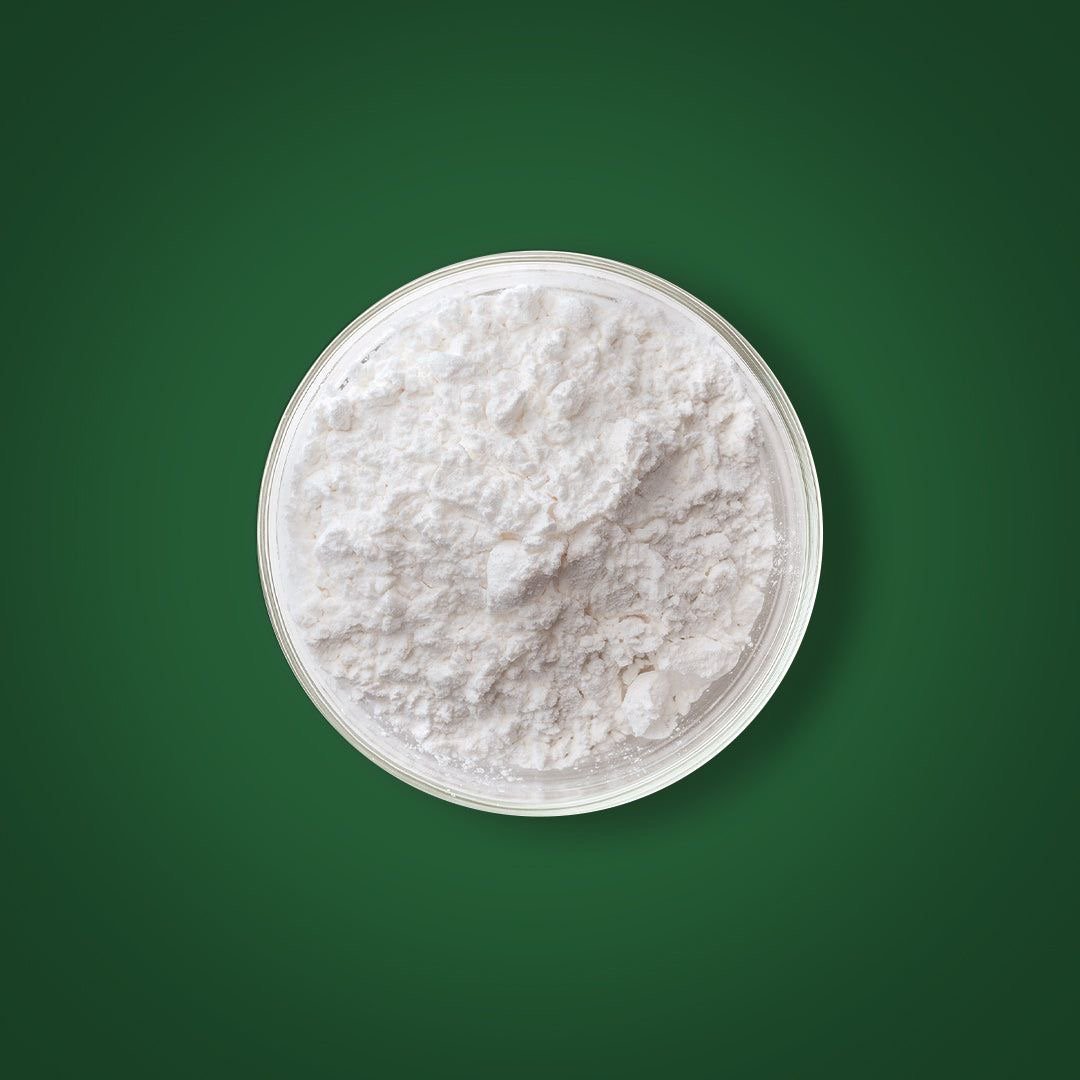

When you opt for high-quality capsules, such as our gelatin capsules or HPMC capsules, you’re investing in capsules that exhibit exceptional performance on high-speed filling machines. Simply put, high-quality capsules minimize waste and maximize your production yield.

On the other hand, low-quality capsules, often imported in bulk in non-temperature-controlled containers, are more likely to introduce production challenges that adversely affect your yield. These problems may include:

- Inaccurate Capsule-to-Tooling Fit: Capsules that don’t fit properly in the tooling are prone to poor assembly, resulting in critical defects like splits and tucks.

- Weak Capsule Shell Construction: Some capsule manufacturers skimp on materials, using the bare minimum necessary to create capsules. When evaluating capsules, consider that the weight of empty capsules can indicate the strength of their walls. Thinner walls lead to more dents, pinholes, and defects like splits and tucks.

- Inadequate Separation Properties: Low-cost manufacturers may push their hard capsule manufacturing machines beyond their process capabilities, hastening the critical drying phase. This leads to variations in the final product, causing capsules to separate unevenly, leading to wasted product, equipment contamination, additional downtime, and frustration for your encapsulation operators.

- Subpar Closure Properties: Sending out finished products that either open or leak before reaching consumers is far from ideal. With a one percent defect rate, every customer opening a 100-count bottle will receive a defective capsule.

How Will Low Yield Affect Your Profitability?

When calculating the true cost of “inexpensive” capsules, you must account for all these factors. Overlooking any of these elements in your analysis will prevent you from assessing the actual total cost of your finished product, which includes:

- Capsule Cost per Thousand Capsules.

- Total Cost of Blended Fill Material per Thousand Capsules.

- Machine Operator Labor Costs (including taxes and benefits).

- Waste Costs (covering capsule and fill material expenses, as well as labor costs associated with troubleshooting, inspections, rework, machine downtime, and the need to operate machinery at slower speeds).

- Return Costs and Reputational Damage (if quality issues are discovered after shipping).

By crunching the numbers, you can see how even a slight increase in waste—say, one capsule resulting in 3% waste compared to another with only 0.03% waste—can significantly impact your profitability. What if the cheaper capsules result in a 5% waste rate? In this perspective, it becomes evident which capsule choice will yield a higher profit margin.

In most cases, opting for higher-quality capsules actually saves you money by reducing waste, downtime, and associated problems.

Conclusion

Success in encapsulation hinges on controlling critical variables, starting with high-quality empty capsules. This encompasses the condition of the filling machines, operator training, and the quality of the fill material. When you invest a bit more in superior capsules, you set your operations team up for success. Furthermore, collaborating with a high-quality capsule supplier enables their technical services team to assist in optimizing your entire capsule filling operation, from machine setup to operator training.

Contact our team of experts for all your burning questions or inquiries: info@forefront-nutraceuticals.com.