By Anna in Blogs 15/10/2023 · 8 minute read

Let’s start of explaining the process of capsulation. The pathway from initial capsule formulation to the finalized product involves detailed processes, each step bound by a steadfast dedication to quality at FOREFRONT Nutraceuticals. Our capsules confine a variety of formulations, from powders and solutions to intricate liquid mixtures, all securely enclosed within a durable shell.

Journey Through Quality Assurance in Capsule Development

Our thorough method for capsule development involves a three-phase quality control testing, consisting of process testing, final product validation, and shelf-life evaluation, each complying with universally accepted industry standards. This threefold testing model ensures every capsule not only meets industry norms but also adheres to the stringent quality standards established by FOREFRONT Nutraceuticals.

Storage of Empty Capsules

Maintaining the high quality of empty capsules is a crucial aspect of our commitment to excellence at FOREFRONT Nutraceuticals. We understand that the integrity of the capsules even before they are filled with active ingredients plays a pivotal role in the final product’s quality. To ensure this, our storage facilities are meticulously designed to preserve the empty capsules in optimal conditions. Controlled temperature and humidity settings are maintained to prevent any moisture absorption or degradation of the capsule shells. Regular inspections and quality checks are conducted during the storage period to identify and rectify any issues promptly.

Shipping Empty Capsules with Quality in Mind

When it comes to shipping our empty capsules to clients and partners, we uphold the same high standards that govern every aspect of our capsule production. Each shipment is carefully packaged to prevent any damage during transit, with a particular focus on protecting the capsules’ structural integrity. We collaborate with trusted logistics partners who understand the sensitivity of pharmaceutical materials, ensuring that our capsules reach their destination in impeccable condition.

Furthermore, we provide detailed storage and handling guidelines to our clients to ensure that the capsules maintain their quality throughout the shipping process and upon arrival at their destination. Our commitment to quality doesn’t end at our facility’s doors; it extends to every step of the journey, from production to delivery, to guarantee that our clients receive only the best empty capsules for their formulations.

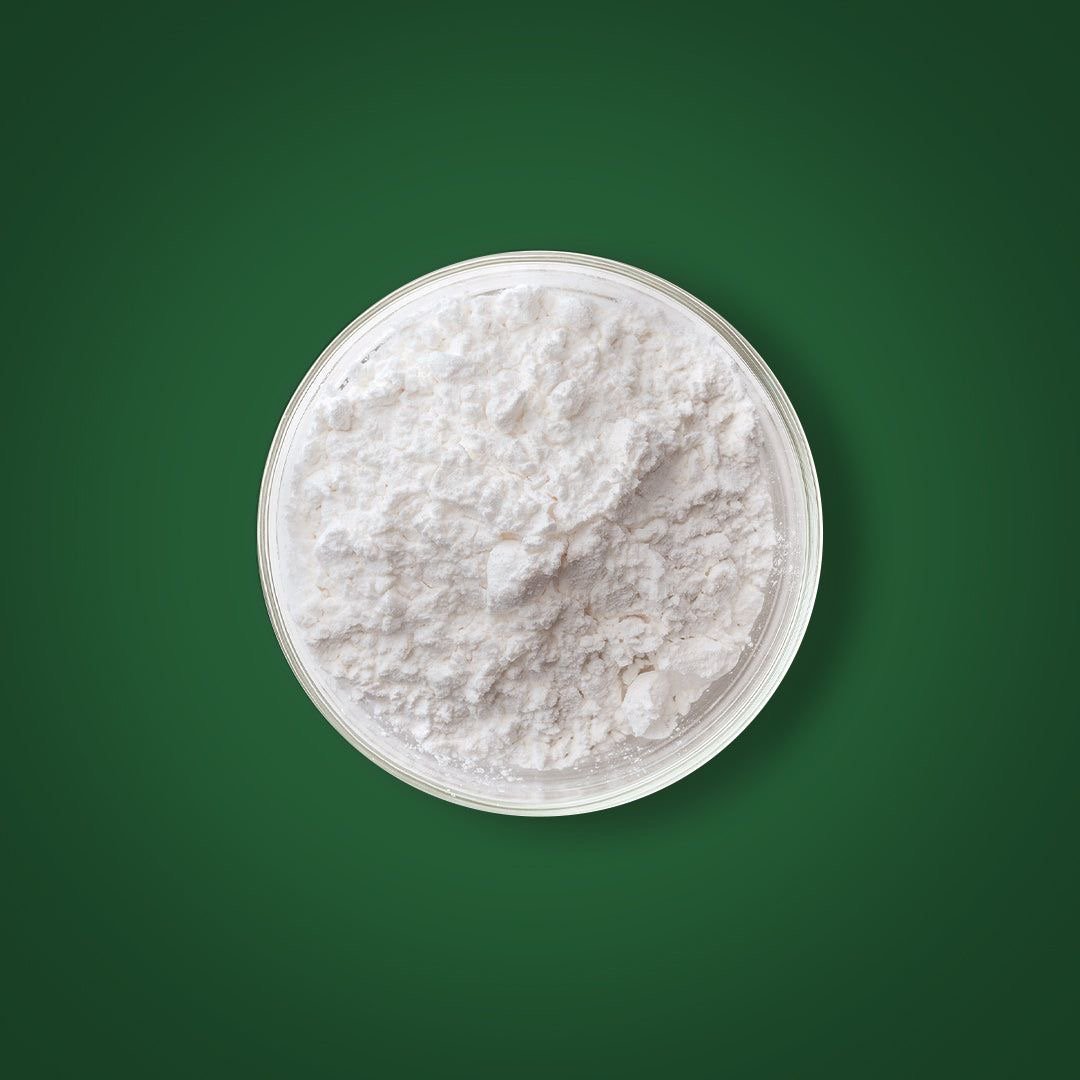

Coicis seed

Coicis seed is difficult to mature, mainly because of its high starch content, large molecular weight and difficulty in absorbing water. In order to simply use coicis seed, coicis seed can be washed, soaked and heated to make its starch alpha, and then used as raw material for food production.

Request Coicis seed here.

Vigilant Selection and Auditing of Raw Materials

Transparency and traceability stand paramount in our process. From origins to supply chains, every aspect of our raw materials is thoroughly scrutinized. Prospective suppliers undergo a rigorous audit, examining their knowledge, manufacturing technologies, supply chain management, packaging, distribution capabilities, and adherence to Good Manufacturing Practice (GMP) norms.

Additionally, on-site audits and testing of various batches ascertain the quality, functionality, and stability of key ingredients like gelatin and HPMC for capsule production, ensuring our ingredients, even colorants, are recognized as safe and compliant with ever-evolving international regulations.

Rigorous Manufacturing and Finalization Controls

In a steadfast commitment to human health, FOREFRONT Nutraceuticals adheres to critical manufacturing controls, governed by prominent global guidelines such as the WHO Technical Reports, Eudralex of the European Union, United States Pharmacopeia (USP), and International Council for Harmonisation (ICH) guidelines.

Our quality tests are performed at strategic intervals throughout the manufacturing process, with data diligently recorded to inform and optimize future processes. During encapsulation, especially of soft gelatin capsules, vital parameters such as thickness, seal integrity, filling, shell weight, moisture level, and visual aspects are stringently controlled.

Post-manufacturing, capsules undergo comprehensive testing, exploring aspects like permeability, potency, impurity content, weight variation, content uniformity, dissolution, moisture content, and more, ensuring each batch is deemed impeccable for sale and its intended use.

Unwavering Commitment to Quality at FOREFRONT Nutraceuticals

At FOREFRONT Nutraceuticals, every stage of manufacturing is under relentless scrutiny.

Our adherence to raw material investigation extends from distribution through to manufacturing, assuring stellar product quality and performance.

In alliance with ISO-certified partners, and practicing Good Manufacturing Practices, we embrace the NSF/IPEC/ANSI 363-2016 GMP standards for excipients, grounded in ISO 9001 principles, in our capsule production for pharmaceutical usage.

We ensure our processes not only embody the pinnacle of quality assurance but also serve as a testament to our unwavering dedication to excellence in the nutraceutical industry. Don’t hesitate to contact us for any inquiries about our products.